Mass timber is one of the fastest-growing innovations in modern construction. At its core, it refers to a family of engineered wood products like cross-laminated timber (CLT) and glued-laminated timber (glulam) that can replace concrete and steel in structural applications.

According to the International Code Council, updates to the 2021 International Building Code now allow mass timber buildings up to 18 stories tall, opening the door for larger and taller projects than ever before.

Real-world examples show how quickly this shift is happening. Brock Commons, an 18-story student residence in Vancouver, was built in just 70 days with a crew of nine installers. More recently, the Ascent tower in Milwaukee reached 25 stories and currently holds the record as the tallest mass timber building in the world.

These projects prove that the material is not only viable but also capable of delivering safe, efficient, and sustainable results at scale.

For builders, owners, and communities, the promise of mass timber is straightforward. It can cut embodied energy compared to concrete and steel, speed up project delivery, and store significant amounts of carbon within the structure itself.

At Seanote Construction, we pay close attention to these kinds of innovations because our clients deserve both safety and long-term value. By combining integrity and transparency, we make sure that new methods like mass timber are evaluated carefully and applied in ways that truly benefit the people we serve across North Central Florida.

Key Takeaways

- Mass timber, including CLT and glulam, is a sustainable alternative to steel and concrete that can now be used in buildings up to 18 stories under updated building codes.

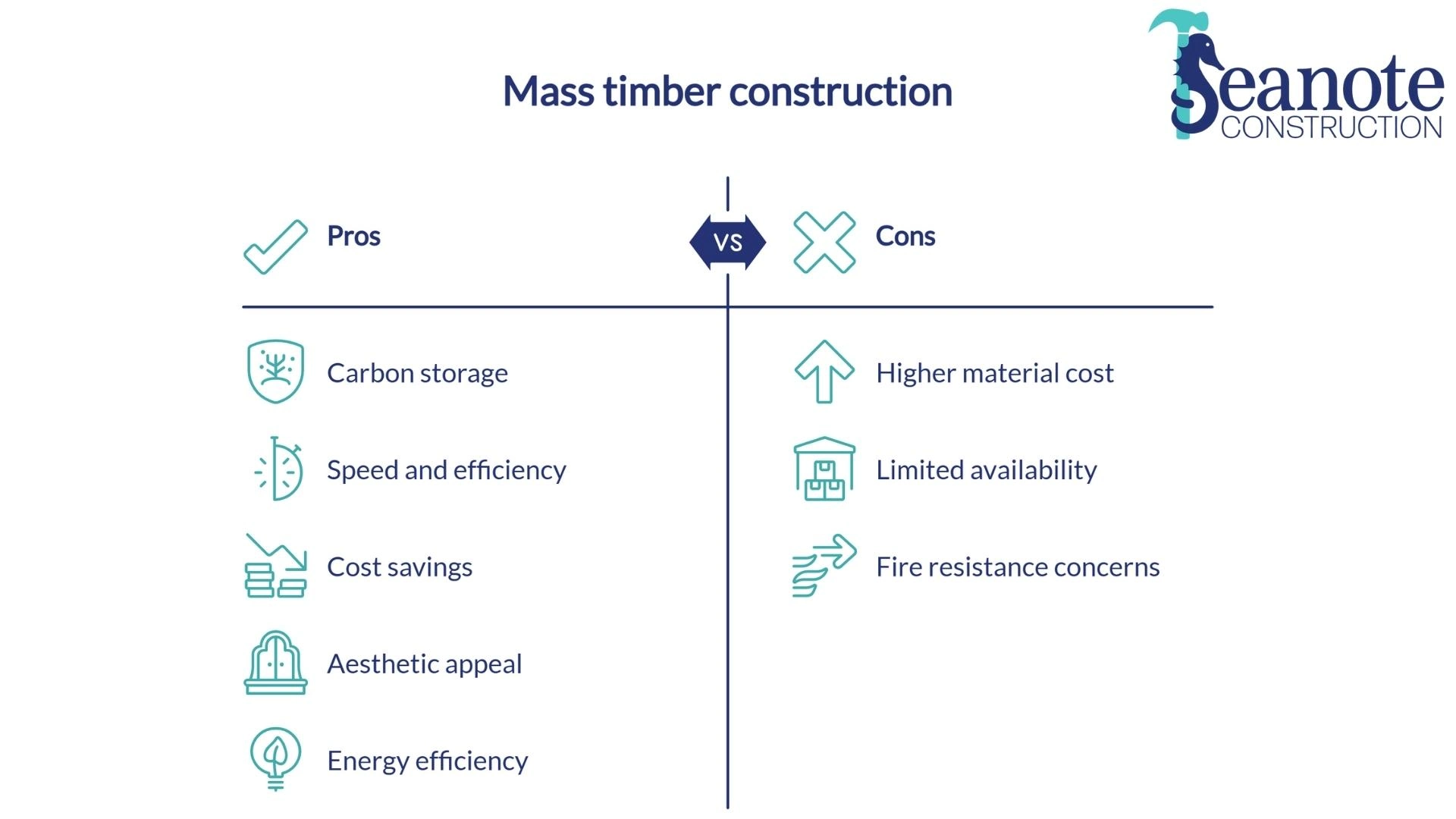

- It offers major benefits such as reduced carbon emissions, faster and more cost-efficient construction, and improved occupant comfort through natural wood aesthetics.

- While promising, mass timber projects face challenges with insurance, permitting, moisture risks, and supply chain limitations, requiring careful evaluation on a project-by-project basis.

What Is Mass Timber?

Mass timber is a category of engineered wood products designed to serve as primary structural elements in modern buildings.

Unlike traditional light-frame construction, which uses smaller dimensional lumber, or heavy timber, which relies on large solid wood beams, mass timber products are manufactured by layering, bonding, or doweling pieces of wood into larger, stronger components. The result is a material that is predictable, uniform, and capable of carrying loads similar to steel or concrete.

At its core, mass timber is not a single product but a family of systems. The most common are cross-laminated timber (CLT) panels, glued-laminated timber (glulam) beams and columns, nail-laminated timber (NLT) floor decks, dowel-laminated timber (DLT), and structural composite lumber (SCL).

Each product is designed for a specific role, like spanning floors, forming walls, or carrying vertical loads. Together, they create complete building systems that can scale from single-family homes to mid-rise offices and, under the latest codes, even high-rise towers.

The appeal of mass timber comes from its ability to combine structural strength with sustainability. By using wood harvested from responsibly managed forests, the material stores carbon while reducing the need for energy-intensive steel or concrete. This dual benefit is why mass timber has been called both a construction method and a climate solution.

5 Types of Mass Timber Products

Each type of mass timber has unique characteristics that make it suitable for different applications. Here are the most widely used options in modern construction.

1. Cross-Laminated Timber (CLT)

CLT is made by stacking layers of lumber at right angles and bonding them into large panels. This cross-laminated design creates strength in two directions, making CLT ideal for floors, walls, and roofs.

Panels can be prefabricated to size, which reduces waste and speeds up installation on site. CLT is often chosen for projects that require quick assembly and strong lateral stability, such as mid-rise housing and schools.

2. Glued-Laminated Timber (Glulam)

Glulam consists of smaller boards glued together in parallel to form strong beams or columns. Because it can be shaped into curves and long spans, glulam is often used for open spaces like atriums, gymnasiums, and airports.

In mass timber buildings, glulam commonly serves as the vertical and horizontal structural frame, carrying heavy loads while allowing for exposed finishes that increase the natural look of wood.

3. Nail-Laminated Timber (NLT)

NLT is created by stacking dimensional lumber side by side and fastening it with nails to form a solid panel. It is one of the oldest forms of mass timber and is cost-effective because it uses standard lumber sizes.

NLT is frequently used for floor and roof decks in commercial or institutional buildings where speed and affordability are priorities. While it does not provide the same cross-laminated strength as CLT, it remains a reliable choice for certain structural applications.

4. Structural Composite Lumber (SCL)

SCL is an umbrella term that includes laminated veneer lumber (LVL) and parallel strand lumber (PSL). These products are engineered by bonding wood veneers or strands under heat and pressure, resulting in consistent, high-strength members.

SCL is commonly used for beams, headers, and long-span applications where uniformity and performance are critical. Because it is factory-made, SCL minimizes defects that might appear in solid lumber.

5. Dowel-Laminated Timber (DLT)

DLT is similar to NLT but uses wooden dowels instead of nails or adhesives to bind the boards together. This makes it a fully wood-based product that appeals to designers seeking an adhesive-free, recyclable system.

DLT panels can be manufactured with milled profiles to allow easy integration of acoustical treatments or mechanical systems. They are especially popular in Europe and are gaining ground in North American markets.

Building Codes and Fire Safety for Mass Timber

One of the most common questions about mass timber is whether it can meet modern safety requirements.

For decades, tall wood buildings were limited by code restrictions that capped height or use. That changed with the 2021 International Building Code, which now allows mass timber buildings up to 18 stories depending on the construction type.

This milestone opened the door for projects like the 25-story Ascent tower in Milwaukee, which has become the tallest mass timber building in the world.

Fire safety is often misunderstood when it comes to wood construction. Unlike light-frame lumber, mass timber is engineered to perform predictably under fire conditions.

Large members form a protective char layer on the outside, which insulates the structural core and slows combustion. Tests by the U.S. Forest Service showed that unprotected glulam columns can achieve a three-hour fire resistance rating through charring alone.

When combined with encapsulation, sprinklers, and modern detection systems, mass timber buildings can meet or exceed the same fire standards applied to steel or concrete.

Beyond fire safety, building codes also account for structural performance, acoustics, and durability. Engineers often use hybrid systems that pair mass timber with concrete or steel cores for additional stiffness and vertical load resistance. These solutions give designers more flexibility while still delivering the speed and sustainability benefits of timber.

4 Benefits of Mass Timber

Mass timber is gaining momentum because it delivers measurable advantages over traditional concrete and steel.

1. Sustainability and Carbon Storage

Wood is the only major structural material that actively stores carbon. For example, the Brock Commons student residence in Vancouver locked in the equivalent of 1,753 metric tons of CO₂ within its structure. By using renewable, responsibly harvested wood, mass timber reduces embodied energy compared to steel and concrete.

2. Speed and Labor Efficiency

Prefabricated panels and beams arrive ready to assemble, cutting time on site. Brock Commons was erected in just 70 days with a crew of nine installers. Industry data shows mass timber projects can be completed 20 to 30 percent faster than conventional builds.

3. Cost and Economic Factors

Mass timber can reduce costs by shortening construction schedules and requiring fewer workers. While material prices may be higher per unit than concrete or steel, savings come from less labor, smaller crews, and reduced crane time. Long-term operating costs also improve due to energy efficiency.

4. Aesthetic and Human Comfort Benefits

Exposed timber creates warm, natural interiors that improve occupant comfort and well-being. Studies have linked wood environments with reduced stress and improved productivity, making it a popular choice for offices, schools, and residential buildings.

Challenges and Limitations

Mass timber offers many benefits, but it is not the right solution for every project. Understanding the challenges helps set realistic expectations.

Insurance and Permitting

Because mass timber is still new in many regions, some insurers and permitting authorities are cautious. Owners may face higher premiums or longer approval times until codes and policies fully adapt.

Acoustic and Vibration Performance

Timber floors can transmit sound and vibration more easily than concrete. Designers often add layers such as topping slabs, acoustic mats, or suspended ceilings to meet comfort standards.

Moisture and Installation Risks

Wood must be protected from prolonged exposure to rain during shipping and installation. Careful sequencing and temporary coverings are essential to avoid warping or mold.

Supply Chain and Market Maturity

Not all regions have local suppliers or fabrication facilities. Transporting large panels long distances can add cost and complexity. In areas where supply is limited, pricing may be less competitive compared to concrete or steel.

Real-World Case Studies Using Mass Timber

Mass timber is no longer a concept. These projects show how it performs at scale.

Ascent, Milwaukee

Completed in 2022, Ascent is a 25-story residential tower that currently holds the record as the tallest mass timber building in the world. The structure includes 19 stories of timber above a concrete podium.

Fire testing confirmed that its glulam columns could achieve a three-hour fire rating, proving mass timber can meet the highest safety standards.

Brock Commons, Vancouver

This 18-story student residence at the University of British Columbia became a landmark for mass timber construction. Its superstructure was completed two months ahead of schedule. The building also stored more than 1,700 metric tons of carbon within its structure.

619 Ponce, Atlanta

Located in Georgia, 619 Ponce is an office building that demonstrates the role of local forestry in mass timber construction. By sourcing regionally, the project reduced transportation impacts while supporting local jobs. It shows how mass timber can bridge sustainability goals with regional economic development.

House in a Garden, Miami (Florida)

This 1,800-square-foot home in Miami’s Coconut Grove neighborhood is the first mass timber project completed in Miami-Dade County. It uses locally sourced Southern yellow pine in CLT panels and reduces embodied carbon while respecting the region’s architectural character.

The project broke new ground dealing with hurricane-prone building codes and regulatory reviews.

Is Mass Timber Right for Your Project?

Mass timber is an exciting option, but it is not always the right fit. Here are the main factors to consider when deciding if it suits your goals.

When Mass Timber Makes Sense

- You want to reduce embodied carbon and support sustainable building.

- Speed of construction is important to save on labor and financing costs.

- Exposed wood aesthetics align with your design vision.

- Your project is mid-rise to high-rise and can take advantage of code allowances for up to 18 stories.

- Local suppliers or shipping routes make mass timber materials accessible.

When Other Materials May Be Better

- Insurance costs or permitting challenges outweigh potential benefits.

- Your building program requires spans or vibration performance that are better handled by concrete or steel.

- Moisture risks during long installation schedules cannot be fully managed.

- Local supply chains are immature, making pricing less competitive.

Florida Considerations

Florida’s climate and regulatory environment add unique factors. The House in a Garden project in Miami showed that mass timber can be approved even in a hurricane-prone county, but it required careful handling of codes and design standards.

Moisture management and hurricane resistance must be planned from the start. For many residential and light commercial projects, hybrid approaches that combine timber with conventional systems may provide the best balance of cost, safety, and speed.

At Seanote Construction, we evaluate each project based on real conditions, not trends. Our role is to give clients a clear picture of whether innovative materials like mass timber make sense, and if not, to recommend alternatives that achieve the same long-term goals.

Ready to Build with Confidence?

Mass timber is reshaping what is possible in modern construction. It delivers strength, speed, and sustainability, with proven results. While it is not the right fit for every project, its potential is undeniable when applied with care and skill.

What matters most is having a partner who will guide you through the options with honesty and precision. At Seanote Construction, we stand apart by combining professional experience with integrity and a problem-solving mindset.

If you are planning a project in Gainesville, Ocala, Alachua, or anywhere along the I-75 corridor, we invite you to connect with us. Visit our contact page to start a conversation and see how building with a partner who always has your back can make the difference.